Unveiling the SkyLoc™ QL™ Series

A New Era of Structural Panel Fasteners!

Skybolt, a trusted leader in aerospace and industrial fastening solutions, today announced the launch of its SkyLoc™ QL™ Series, a next-generation family of self-locking structural panel fasteners engineered for high-load, high-vibration environments where reliability, serviceability, and performance are critical.

Designed to support modern aerospace, defense, motorsport, and advanced industrial applications, the SkyLoc™ QL™ Series delivers structural load capacity with rapid installation and removal, addressing the growing demand for fasteners that reduce maintenance time without compromising strength or durability.

Skybolt™ innovations include easily replaceable locking receivers (including threaded receivers):

Structural Performance Meets Rapid Access

Structural panel fasteners are used where removable panels must carry significant shear and tensile loads while remaining resistant to vibration, fatigue, and repeated service cycles. Typical applications include aircraft engine access panels, nacelles, avionics enclosures, flight-critical structures, and high-performance motorsport bodywork.

The SkyLoc™ QL™ Series are purpose-built for these environments, offering:

- High shear and tensile load capability

- Positive locking under severe vibration

- Long service life with high cycle performance

- Fast, tool-controlled installation and removal

- Consistent clamp load across a wide grip range

- Fast Lead Times

Two Complementary Product Families

The SkyLoc™ QL™ Series consists of two distinct yet complementary fastening families:

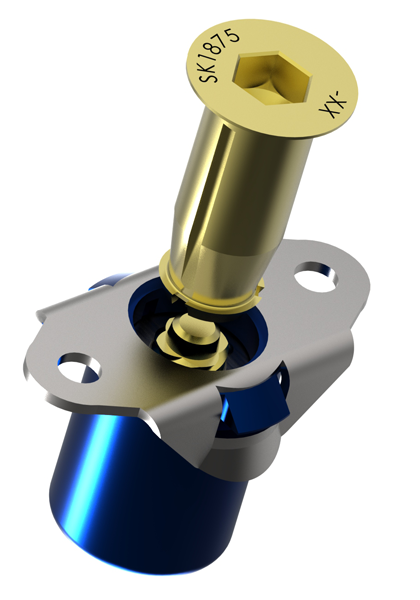

SkyLoc™ SN (Stud-Nut) Family

Engineered for quick-release structural applications, the SkyLoc™ SN family features a multi-lead thread with an integrated locking mechanism that achieves secure engagement in just a few turns. This design allows for rapid access while maintaining structural integrity under vibration and dynamic loading.

SkyLoc™ SN fasteners are available with three head styles to meet a wide range of design and ergonomic requirements:

- Flat Head — for flush or low-profile installations

- Pan Head — for enhanced grip and visual confirmation

- Knurled Head — for improved handling in gloved or tool-limited environments

The SN family is supported by a complete system of matched receptacles and retaining solutions, enabling reliable installation in composite, metallic, and mixed-material structures.

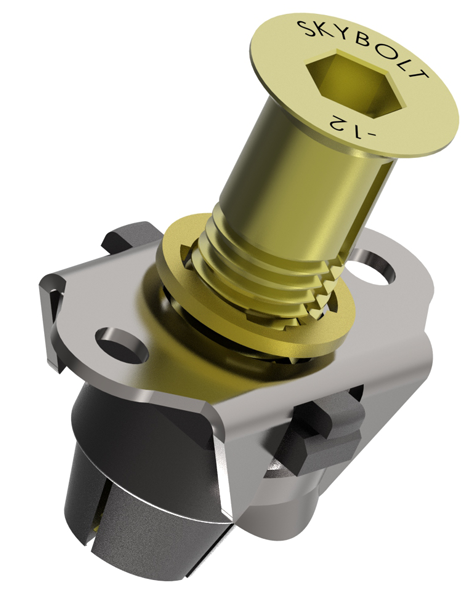

SkyLoc™ EXT (External-Thread) Family

The SkyLoc™ EXT family is designed for applications requiring maximum structural performance and robust vibration resistance. Utilizing an external-thread configuration with a beam-style locking element, the EXT family delivers exceptional resistance to loosening, long service life, and tolerance for installation variability such as misalignment or curved panel geometry.

The EXT family is well-suited for primary and secondary structural panels where repeatable clamp load, durability, and ease of maintenance are essential.

Designed for Modern Programs

Both SkyLoc™ families are available in multiple sizes, grip ranges, and material options to support evolving aerospace and defense requirements. Receptacle designs include a radial float to accommodate misaligned holes, curved surfaces, and manufacturing tolerances, reducing installation stress and improving long-term reliability.

Leadership Perspective

“SkyLoc™ represents a major step forward for Skybolt and for our customers,” said Ned Bowers, CEO of Skybolt. “We engineered this product line to meet the real-world demands of today’s aircraft and high-performance systems—where structural strength, vibration resistance, and rapid access all matter equally. SkyLoc™ allows engineers to design with confidence while giving maintenance teams the speed and reliability they need in the field.”

“The Drone Industry has re-written the play book. Innovation and efficiency are key drivers. The cost equation by reducing design, production, and lead times is what separates Skybolt from the rest of the field,” according to Bowers. Ned Bowers notes, he began his engineering career on the S1C stage and F1 engines on the Saturn V. “From Mercury, Gemini, and Apollo, we went to the moon faster than some vendors deliver product”. Skybolt™ delivers!

About Skybolt™

Headquartered in Leesburg, Florida, Skybolt™ is a leading manufacturer of high-performance fastening systems for aerospace, defense, and industrial applications. With decades of experience in quick-release and structural fastening technology, Skybolt™ is committed to delivering innovative, reliable solutions that support the most demanding environments.

For more information about the SkyLoc™ Series, visit www.skybolt.com or contact Skybolt directly!